Lineshaft Conveyors

Lineshaft Conveyors represent a unique concept in powered conveyors. They have the capability of accumulating products with minimum back pressure. Typical characteristics include quiet operation and easy maintenance.

Lineshaft Conveyors

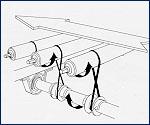

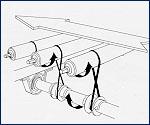

Lineshaft Conveyors are powered by a drive shaft that spans the full length of the conveyor and transmits power to the rollers via a drive spool and belt. When back pressure is applied to the conveyed product, the spools driving the rollers will slip on the shaft allowing the product to accumulate with a minimum amount of back pressure. Applications include transportation, minimum pressure accumulation, zero pressure accumulation, and sortation.

Lineshaft Conveyors

Lineshaft Conveyors are available with a number of formed frame specifications, including galvanized. Between frame dimensions from 13″ – 28″ in full inch increments are available with 1.375 diameter galvanized rollers. Floor supports are adjustable from 36″ to 48″ from floor to top of rollers. The drive shaft is a 1″ steel shaft with 2″ Delrin drive spools. The drive belts are 3/16″ urethane, enclosed in a full length spool drive guard.

Bearings

Bearings in lineshaft conveyor are sealed, pre-lubricated, and self-aligning. Drive units can be mounted to curves, spurs, and straight sections to provide power. 5/8″ dia. ceiling hangers are available for overhead mounting. Curves are available in 30°, 45°, 60°, and 90° modules, spurs are available in 30° and 45° models. Curves will have tapered rollers.

Lineshaft Conveyors

Lineshaft Conveyors can be fitted with many optional accessories including; urethane belt transfers to re-direct product 90° onto another conveying line, live gates to allow access to equipment, zero pressure accumulation models, dual shaft configuration, pusher devices to diver product to other conveying lines, crossover rollers, stops, brakes, and traffic cops.

Lineshaft Conveyors are powered by a drive shaft that spans the full length of the conveyor and transmits power to the rollers via a drive spool and belt. When back pressure is applied to the conveyed product, the spools driving the rollers will slip on the shaft allowing the product to accumulate with a minimum amount of back pressure. Applications include transportation, minimum pressure accumulation, zero pressure accumulation, and sortation.

Lineshaft Conveyors are powered by a drive shaft that spans the full length of the conveyor and transmits power to the rollers via a drive spool and belt. When back pressure is applied to the conveyed product, the spools driving the rollers will slip on the shaft allowing the product to accumulate with a minimum amount of back pressure. Applications include transportation, minimum pressure accumulation, zero pressure accumulation, and sortation. Lineshaft Conveyors are available with a number of formed frame specifications, including galvanized. Between frame dimensions from 13″ – 28″ in full inch increments are available with 1.375 diameter galvanized rollers. Floor supports are adjustable from 36″ to 48″ from floor to top of rollers. The drive shaft is a 1″ steel shaft with 2″ Delrin drive spools. The drive belts are 3/16″ urethane, enclosed in a full length spool drive guard.

Lineshaft Conveyors are available with a number of formed frame specifications, including galvanized. Between frame dimensions from 13″ – 28″ in full inch increments are available with 1.375 diameter galvanized rollers. Floor supports are adjustable from 36″ to 48″ from floor to top of rollers. The drive shaft is a 1″ steel shaft with 2″ Delrin drive spools. The drive belts are 3/16″ urethane, enclosed in a full length spool drive guard. Bearings in lineshaft conveyor are sealed, pre-lubricated, and self-aligning. Drive units can be mounted to curves, spurs, and straight sections to provide power. 5/8″ dia. ceiling hangers are available for overhead mounting. Curves are available in 30°, 45°, 60°, and 90° modules, spurs are available in 30° and 45° models. Curves will have tapered rollers.

Bearings in lineshaft conveyor are sealed, pre-lubricated, and self-aligning. Drive units can be mounted to curves, spurs, and straight sections to provide power. 5/8″ dia. ceiling hangers are available for overhead mounting. Curves are available in 30°, 45°, 60°, and 90° modules, spurs are available in 30° and 45° models. Curves will have tapered rollers. Lineshaft Conveyors can be fitted with many optional accessories including; urethane belt transfers to re-direct product 90° onto another conveying line, live gates to allow access to equipment, zero pressure accumulation models, dual shaft configuration, pusher devices to diver product to other conveying lines, crossover rollers, stops, brakes, and traffic cops.

Lineshaft Conveyors can be fitted with many optional accessories including; urethane belt transfers to re-direct product 90° onto another conveying line, live gates to allow access to equipment, zero pressure accumulation models, dual shaft configuration, pusher devices to diver product to other conveying lines, crossover rollers, stops, brakes, and traffic cops.

.jpg)